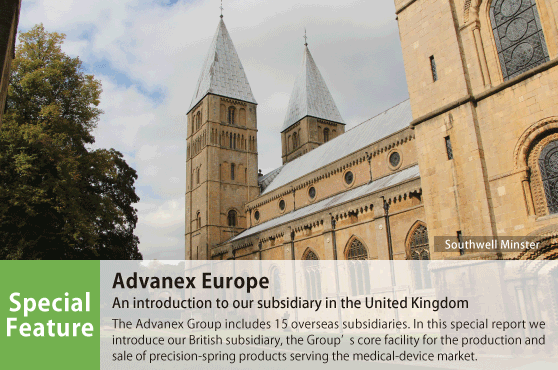

The head office and factory of Advanex Europe Ltd. are located in the town of Southwell in Nottinghamshire, about two hours' drive north of London. At the center of this town of 7,000 people is Southwell Minster, built in 1150. Also part of Advanex Europe is Bilborough Plant, an hour away in a suburb of the city of Nottingham. Each plant employs just fewer than 90 people for a total workforce of 174.

Advanex Europe was founded in 1988 as a wholly owned subsidiary. The company began as a producer for the European market of shutters for floppy disks-a niche in which Advanex enjoyed a 90% share of the world market. Paul Clifford, originally an engineer, became the company's managing director in 1991. In 1993 the company acquired a leading spring manufacturer in nearby Bilborough, which is now the company's Bilborough Plant.

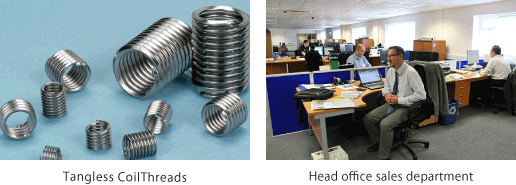

Net sales of Advanex Europe in the previous fiscal year (year ending March 31, 2014) were approximately ¥1.6 billion. Operating income ammounted to approximately ¥140 million. With an operating margin of approximately 9%, Advanex Europe is the Advanex Group's most profitable subsidiary. Core products are precision springs for medical devices as well as Tangless CoilThreads, reinforcing parts used in fastening applications for the aircraft and automobile industries. These two product segments comprise 43% and 40% respectively of Advanex Europe's sales and are key drivers of the subsidiary's high profitability.

Getting ahead in the medical-equipment business requires many years of experience, and the trust you build as a result of that. We launched our medical-equipment operations in 1997, but our growth really took flight in 1999. That was when a major European medical-equipment manufacturer placed an order with us for precision springs for use in aspirators, a component of the metered dose inhalers used to treat asthma. Of course, metered dose inhalers require highly accurate measurement of each dose. In 1998, we received an order to develop precision springs for use in the measurement counters of aspirators. Other companies were unable to meet the customer's standards, but Advanex did the development work at Kashiwazaki Plant in Japan and we won the order. After we imported three units of production equipment from Japan, we launched production. Today we produce three types of precision spring, including precision springs for aspirators of other manufacturers. Combined production volume at our two plants for medical equipment customers is over 200 million springs per year. We expect that production volume to increase every year. In addition to metered inhalers, Advanex Europe manufactures precision springs auto-injection pens individuals can use at home to administer stiff-shoulder medication, blood-sugar-lowering medicines and the like.

Getting ahead in the medical-equipment business requires many years of experience, and the trust you build as a result of that. We launched our medical-equipment operations in 1997, but our growth really took flight in 1999. That was when a major European medical-equipment manufacturer placed an order with us for precision springs for use in aspirators, a component of the metered dose inhalers used to treat asthma. Of course, metered dose inhalers require highly accurate measurement of each dose. In 1998, we received an order to develop precision springs for use in the measurement counters of aspirators. Other companies were unable to meet the customer's standards, but Advanex did the development work at Kashiwazaki Plant in Japan and we won the order. After we imported three units of production equipment from Japan, we launched production. Today we produce three types of precision spring, including precision springs for aspirators of other manufacturers. Combined production volume at our two plants for medical equipment customers is over 200 million springs per year. We expect that production volume to increase every year. In addition to metered inhalers, Advanex Europe manufactures precision springs auto-injection pens individuals can use at home to administer stiff-shoulder medication, blood-sugar-lowering medicines and the like.

Tangless CoilThreads are reinforcing components for threaded bores. They're mainly used in aircraft and automotive applications. We started producing these components at Southwell in 1995, when we transferred some production equipment from Fukushima Plant (closed in 2009) in Japan. Advanex Europe offers Tangless CoilThreads in a range of sizes, exporting them as standard products chiefly to markets in the United States and various European countries, as well as Japan and other Asian countries.

Advanex Europe is the largest company in Southwell. In 2012 the local newspaper, the Nottingham Post, selected us as gNottingham's best company.h We try to run our business as a company with solid roots in the community: for example, we bestow the gAdvanex Awardh to outstanding students at the local technical university. In our near-term plans, we aim to increase sales to the medical-device sector and bolster our sales efforts toward the automotive industry.