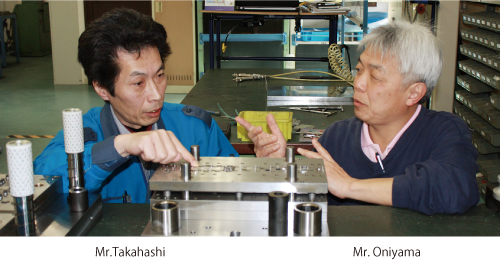

How would you describe Mr. Takahashi as an engineer?

Oniyama:He is a man interested in everything around him, jumping at every chance to learn new things and make something new. A man who never abandons what he started halfway and sees his initiatives all the way through to completion. Also, he is very sociable, a really good listener. He also always tries to come up with the best ways to nurture younger workers and is a great influence for his subordinates. He may sometimes overdo the talking, though... (laughs)

Mr. Takahashi, when did you first get interested in craftsmanship?

Takahashi:I have always been tinkering with all kinds of things - my parents' influence, I guess. But I did not enter Advanex just because I like making things. After entering the company, I spent days and days in strenuous training and was too busy to feel that what I was doing was, in fact, interesting. I devoted myself to craftsmanship out of competitive spirit - because I wanted to make things better than everyone around me, because I wanted to be praised. And, little by little, I started to feel the sense of accomplishment from the work I do, and that is a pleasing feeling for sure.

Are there any aspects of craftsmanship you are particularly fussy about?

Takahashi:In short, my motto is "destroy and create" I do not think that the word "improvement" only means enhancing the functions. For me, "improvement" means to eliminate waste to the maximum extent possible and give the product new value in as many aspects as possible. Therefore, when I'm given some established technology or a system, the first thing that crosses my mind is "your time is over, pal". And when I manage to use the old to create something new and achieve the very result I aimed for, the sense of accomplishment is amazing. This feeling is the greatest motivation for me in my work.

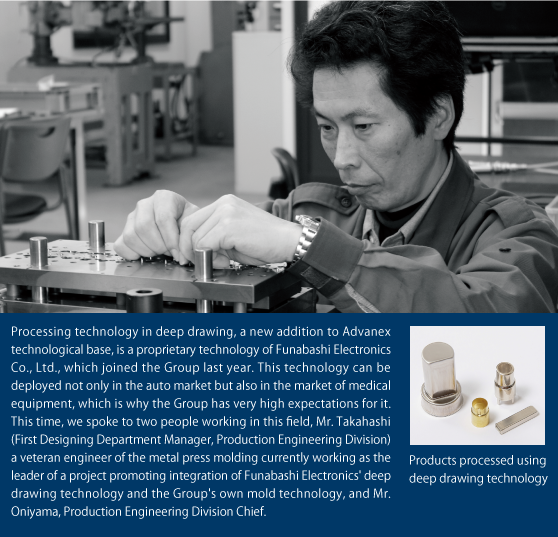

Do you have any interesting stories about the time when you first started working with deep drawing technology molds?

Takahashi: I felt that in order to really succeed to the Funabashi Electronics' deep drawing technology and develop it further, I have to cease being a "higher‐up" from the parent company and become "one of the guys", so to speak, a comrade who shares both joys and sorrows of the workplace. So I put on the uniform worn by Funabashi Electronics' employees, and learned the technology on the spot, getting my hands dirty with oil, working just as everyone else. Deep drawing technology is by no means a simple one, and when using it one has to be as delicate as if dealing with a living creature, always being attentive to changes in stress imposed on the materials and the thickness, using one’s fingertips to adjust tiny errors the machine just does not see. A few days ago, the company was finally transferred to Advanex and we launched the production of the first product using the new technology, and that was quite an ordeal.I was working every waking moment doing inspections again and again and finally managed to combine our own mold technology and the processing technology of Funabashi Electronics. If this technology takes roots in the Group in the future, we will be able to offer products manufactured using this technology anywhere across the world, which will definitely increase our corporate value.

And now for the last question. What, in your opinion, does it mean to be a Master Engineer?

Takahashi:I do not count myself as one. Well, it is someone on a never-ending quest to improve his technology, someone who is always creating new things... That is a real master.