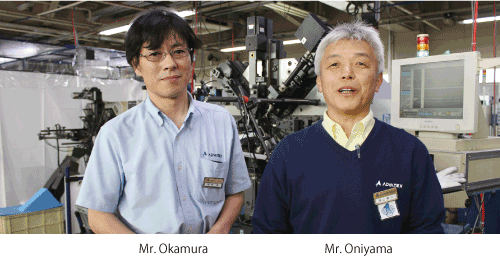

Mr. Oniyama, whatfs your take on the engineer as gartisanh?

OniyamaFTo me, gthe engineer as artisanh means a person who is always incorporating new technologies into his work, who has a concept and draws on it to create new things. At Advanex, Mr. Okamura is the head of a group of engineers who are doing just that. They have a keen sense of responsibility, because everything depends on them. Our competitive position originates in our technical capabilities, so we are convinced that gthe engineer as artisanh is a precious treasure for us. The most important part of my job is to develop other gartisan engineers.h Thatfs my mission.

Mr. Okamura, how did you come to work at Advanex?

OkamuraFEver since I was a little boy Ifve enjoyed taking apart things like TVs and radios and putting them back together again. I must have been born with a passion for making things. I started handling lathes and other fabrication machinery from my days as a student, and in 1983 I joined Advanex. I started out as a torsion spring engineer, responsible for duties ranging from designing molds and planning machine layouts to production.

In those days we still had an old-fashioned culture of learning engineering by watching. I carefully watched the work of senior employees and gathered a wide range of experience. The experience I gained in those days comes in handy even now.

What difficulties did you encounter in developing the Tamont?

OkamuraFUnlike locking mechanisms developed by other companies, Tamont fits on the outside of ordinary nuts used to fasten bolts. When the customer first approached me about fashioning a screw that would not loosen, I looked at the plan drawings and got a visceral feeling that it was impossible. The structure seemed too complicated. But I started developing the prototype by hand, and after repeated trial and error I was able to produce a single product. Drafting the drawings for machine production took about six months. I was troubled by the problem of how to reproduce the item Ifd made by hand using automated equipment, to move the project to mass production. Again I repeated the process of trial and error. It was the most vexing project Ifd ever been tasked with. Mr. Oniyama advised me, gIf you can make it by hand, it can be made by machine.h At last I succeeded in turning the prototype into a product. When I finally set the mold in place and started the machinery for mass production, the feeling of accomplishment was incredible. I was so happy I wept tears of joy.

What kind of company would you like Advanex to become?

OkamuraFTechnological capability is the standard by which customers judge a company, so it plays a vital role in winning the support of customers for Advanex. Similarly, we are keenly aware that our reason for existing is to serve our customers, so it is of primary importance that we possess the technological capability to solve customersf problems, table proposals that address those concerns, and earn customer delight. I want customers to recognize Advanex as a company that always responds to the expectations of customers, so that we can continue to grow in the future.

Passing technology on to the next generation is another important theme. We are committing efforts to cultivating the next generation of artisans. We are steadily teaching the intermediate classes, and training of young artisans is proceeding smoothly as well.

Finally, Mr. Okamura, what kind of person is an gartisan as engineerh in your view?

OkamuraFA person who never says it canft be done.